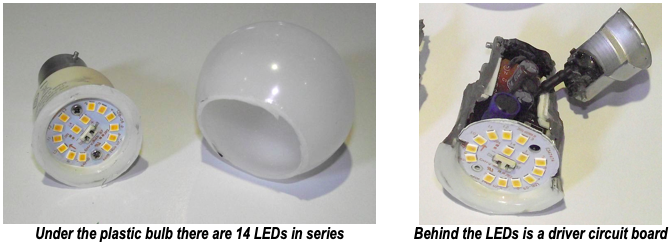

So, what’s inside one of these lights that has the potential to create so much HF interference? We opened up a common Philips 10W lamp with an angle grinder to see what makes it tick.

There are fourteen LEDs wired in series, with a likely working voltage of around 35V. However, the actual voltage is not important. The regulator circuit is there to convert the mains AC to DC then regulate the current flow to an optimum value. In this case it is probably around 250ma.

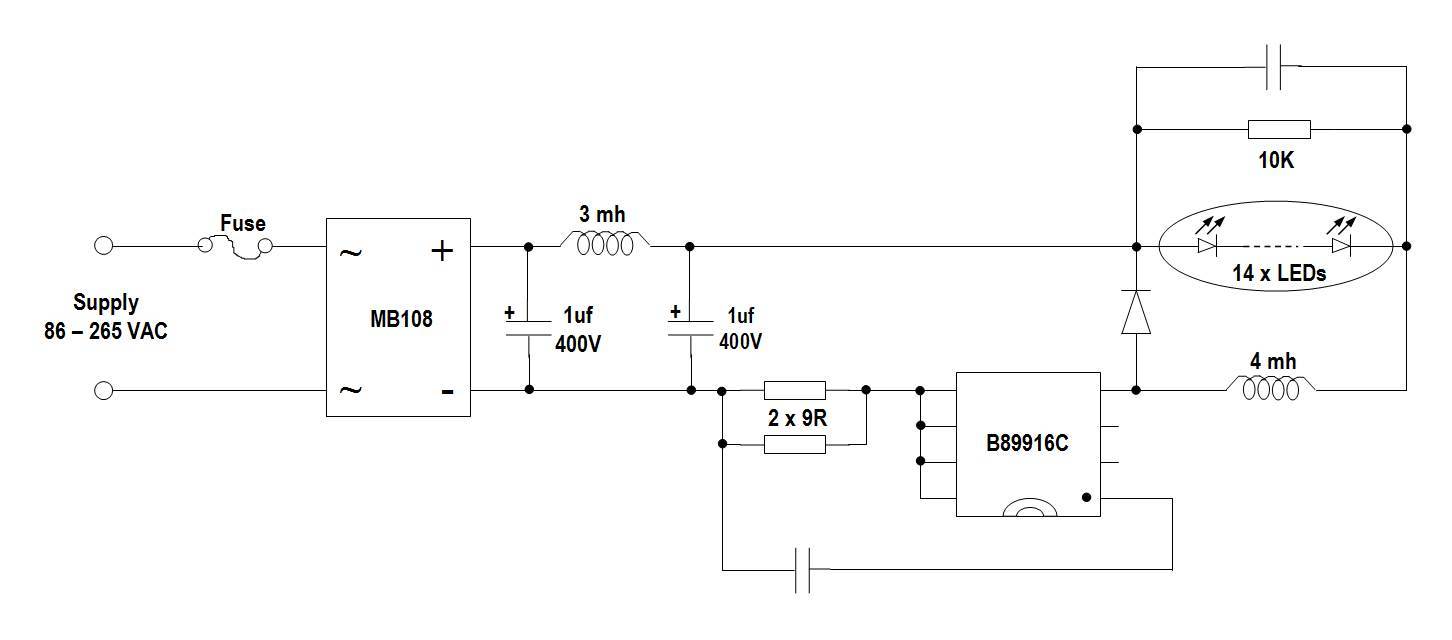

After the circuit board was pried out of the bayonet lamp base and moulded plastic housing, it was possible to perform a full circuit trace. Here is a schematic of what we found inside:

The AC supply couples to a bridge rectifier via a small fuse. If any component shorts out, the fuse would blow before it gets a chance to start a fire. After the bridge of rectified mains there is an all important PI-filter to stop circuit interference from returning back into the AC supply cable. The DC power rail would be around 300V on a 240V supply.

There is a B89916C constant-current regulator chip fed via a current limiting pair of 9 ohm resistors in parallel. The chip has an internal MOSFET that pulses the LEDs at a high rate while the chip monitors the voltage drop across the two 9 ohm resistors. When the target LED current has been reached, the circuit adjusts the pulse rate to maintain that ideal current.

It is these fast rise-time pulses at switching current that have the potential to generate RF interference high into the radio spectrum. This is stopped via some critical parts. A network of Resistor, Capacitor and Inductor in parallel with the LEDs serves to round off these high frequency pulses and suppresses energy out of the RF range. A reversed-biased diode across the output will clamp any negative going EMF transitions coming back from the inductor.

The result is a low-cost LED driver that operates over a wide supply voltage range. There is a lot of smart technology inside the chip which keeps the total component count to a minimum.

These lights sell for around $10 retail. The supplier probably gets it for around $5. For that amount it must be packaged and shipped from halfway around the world. The manufacturer has to make some profit, maybe 50 cents Australian. For the $2 remaining they must source the 35 moulded and customised parts that make up each light, carefully assemble these components and then seal and test the finished product.

From a budget costing perspective it is difficult to understand how this is achievable, yet the proof is there on our supermarket shelves. We have an efficient, light source, consuming barely 12% of the energy of its incandescent predecessor, lighting up our homes for the cost of a cup of coffee and a few biscuits.

As long as it stays out of our radio spectrum, we’re on a good thing.

Thanks to Ian, VK3BUF for this post